Machining is a time-consuming and expensive process. Milling machines can take hours to produce the minor parts for a complex product, and the average machinist can charge over $100 per hour.

It's not just affordable to outsource work to manufacturers - it's necessary. The average company spends more than 40% of its budget developing prototype products, but that leaves less for investment in marketing and other essential aspects of business growth.

With Wayken CNC machining providers from Machines Inc., you can access the precision typically only found in high-volume production shops at a price point that won't break your budget. Eliminate the need to outsource expensive jobs,

Lets's dive deeper into the article to find out the types of prototypes you can get from this platform.

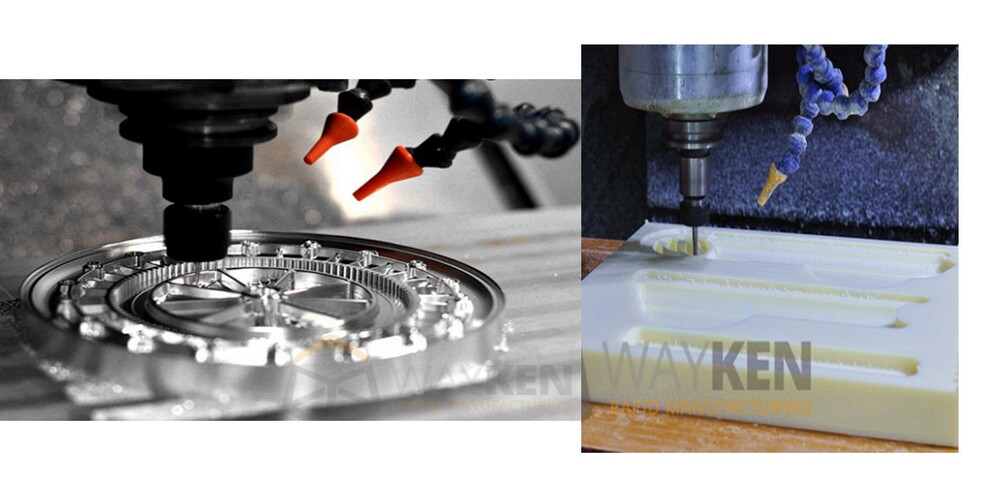

Highly Precise And Complex Prototype Machining

CNC machining is a term used to identify the process of having exact and complex prototype parts machined. These parts can be made in multiple materials and are used in nearly every industry. The benefit of CNC machining is that it can create very intricate or elementary parts depending on your needs.

While CNC machines are most commonly used by manufacturers who produce products in high volumes, they can also be used by companies that need custom-made parts and prototypes made. CNC stands for Computer Numerical Control and refers to how these machines use computers to control their movements. The user can customize the programs depending on the amount of material they want to remove from their prototype.

The three types of prototypes you can get from these platforms are given as follows:

1. Aluminum Prototypes

Aluminum prototypes are one of the most common prototype parts that you can get with CNC machining. Prototypes usually have a one-time production in low volume.

They are also used to test a new design, product, or process. Aluminum is used more often than stainless steel because it's cheaper and lighter than stainless steel.

It has excellent strength at low weight, making it perfect for applications (such as marine vessels and aircraft). As long as you get the right provider for your aluminum prototype machining project, you can receive prototypes that look fantastic and function flawlessly.

2. Engineering Functional Prototypes

The Engineering Functional Prototypes that you can get from Prototype CNC Machining are done either through trial and error or with the help of an expert in your industry. The prototype machines can be used to create parts that are near-perfect imitations of your final product but are not fully functional.

These prototypes can also be used for balancing purposes, allowing you to feel how your product will work before you start manufacturing a mass quantity of them.

This type of Prototype CNC Machining allows you to continue working on other aspects of your project while still having a physical product that will give you some insight into how your final product will work without putting any funds toward manufacturing operations until you are satisfied with its appearance and functionality.

3. Optical Prototypes

Optical Prototypes are the first physical model of your design. It's more important than just meeting the customer's needs because it's the actual thing that the customer sees and uses.

We can accomplish this by using polyurethane casting, CNC machining, and 3D printing for our process. These processes provide us with a wide range of options for efficiently making practical prototypes.

These prototypes provide a more thorough test and review of your final product. Examples include automotive, medical, and consumer electronics products.